30-50tpd peanut oil solvent extraction plant in india

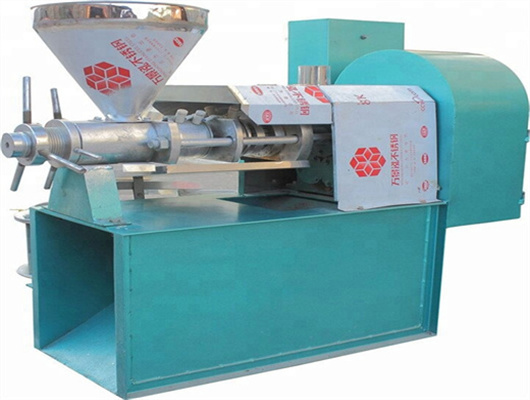

- Usage: Peanut oil extract mill plant

- Type: Peanut oil extract mill plant

- Production Capacity: 10T-3000T/D

- Voltage: 220v / 380v or local voltage

- Power(W): Depend on Peanut oil extract mill plant capacity

- Dimension(L*W*H): Depend on Peanut oil extract mill plant capacity

- Weight: Depend on Peanut oil extract mill plant capacity

- Product name: Peanut oil extract mill plant

- Electric Consumption: Depend on Peanut oil extract mill plant capacity

- Handling capacity: Depend on Peanut oil extract mill plant capacity

- Advantage: High efficiency

- Raw material: Peanut Seed

- Export markets: All over the world

- Delivery time: 25-45 Days

- Machine color: Depend on customers' request

- Supplier Type: Manufacturer

- Suitable for: Peanut and other plants seed

V.B Oil Mills Pvt Ltd – SUNPREETHI OILS

V.B Oil Mills Private Limited Established in 1989 in India. Our company has started as batch solvent extraction plant of 50 TPD. We started processing sunflower oil cake. We expanded to continuous solvent extraction plant of 150 TPD. We further established another solvent extraction plant of 100 TPD. we also have refinery of 50 TPD capacity.

Our scope of work for Solvent Extraction Plant include from concept to commissioning on Turnkey basis. Solvent Extraction Plant available in following capacities: 50 TPD - 100 TPD - 150 TPD - 200 TPD - 250 TPD - 300 Tones Per Day (TPD) Suitable to process following types of Seeds and Oil Cakes: Groundnut - Rapeseed - Cottonseed - Sunflower

Solvent Extraction Plant Manufacturers - N&T Engitech

N&T is a leading Solvent Extraction Plant manufacturer & Exporters with over many years of industry experience professionals. Our solvent extraction process is straightforward and efficient that consumes less hexane, steam, and power. This solvent extraction plant includes three steam ejectors and three pressure reducing stations, which are

The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Continuous Solvent Extraction Plant, Oil Extraction Process

Solvent extraction is a counter-current extraction process for extracting crude edible oil from oilseeds and oil cake using solvent, with Hexane. Hexane-based processes is popular for maximizing oil yield in excess of 95% with a solvent recovery of over 95% which in compare to 60 to 70% oil yield by mechanical expeller pressing. Thus Solvent

Semi Automatic Stainless Steel Herbal Extraction Unit, Capacity: 50 Ltr 5000 Ltr. ₹ 1,49,535 Get Latest Price. Usage/Application: Herbs extraction plant, phytochemicals extraction plant. Material: Stainless Steel. Capacity: 50 ltr 5000 ltr. Machine Type: Semi automatic. Country of Origin: Made in India.

Kamal Solvent Extractions Pvt. Ltd.

Kamal solvent extraction Pvt. Ltd. is a rice bran oil manufacturing unit established by entrepreneurial vision of Mr. Damodar Das Mundra. Established in the year 1989, with an installed capacity of 50TPD, which was later expanded to 150 TPD & is presently having an operational capacity of 500 TPD.

The filtered oil is widely accepted for human consumption. After full pressing the balance cake with 5 – 6% of oil will be transferred to solvent extraction process where the balance 6% oil will be extracted leaving 0.5% to 0.7% will remain the cake after solvent extraction process. Solvent Extraction Process

- What is a solvent extraction plant?

- Solvent Extraction Plant – Mectech Process Engineers. The oil solvent extraction plant comprises of extraction De-solventizing Toaster, a Distillation System and a Solvent Recovery System. The extractor enables removal of the solvent from the meal, toasts the meal to maintain inherent nutrition, and stabilizes its moisture as well as temperature.

- What is solvent extraction?

- Solvent extraction is a counter-current extraction process for extracting crude edible oil from oilseeds and oil cake using solvent, with Hexane. Hexane-based processes is popular for maximizing oil yield in excess of 95% with a solvent recovery of over 95% which in compare to 60 to 70% oil yield by mechanical expeller pressing.

- Can SpecTec provide a continuous solvent extraction plant?

- Spectec Techno Projects Pvt. Ltd, can provide a complete Continuous Solvent Extraction Plant for the capacity ranges from 50 TPD TO 2000 TPD. Preparation is the process of properly preparing seeds for extraction of oil. A particular seed may contain from 20 % ¨C 50 % oil, (depending on the seed and and geographical location).

- What is a continuous solvent plant in India?

- A continuous solvent plant in India designed and supplied by Mectech are the most e?cient and economical in processing cost.