raw and cooked expeller peanut oil equipment in togo

- Model Number: press on nail boxes

- Industrial Use: Cosmetic

- Use: Nail Polish Oil

- Paper Type: Paperboard

- Printing Handling: Matt Lamination, Varnishing, Stamping, Embossing, Glossy Lamination, UV Coating, VANISHING, Gold Foil

- Custom Order: Accept

- Feature: Recyclable

- Shape: Satin Lined Boxes

- Box Type: Rigid Boxes

- Product name: nail box packaging

- Size: Cutomized Sizes

- Logo: Customer's Logo

- Usage: custom nail packaging box

- Color: CMYK, Pantone/PMS, Flexo, Offset. etc

- Material: paperboard,kraft paper,corrugated paper in A,B,C,E,F,AB,BE,BC

- Sample time: 3-5 working Days For Sample; 9-12 working days for mass production

- Sample: Stock Sample is free

- Accessory: Ribbon, Drawstring, Plastic Handle, PVC window, Magnet seal or others

- Keyword: box packing nails

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

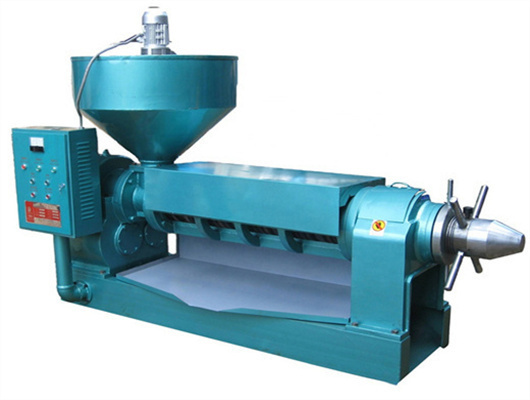

It was powered by a 1 hp three-phase electric motor. The expeller has an average extraction efficiency and capacity of 72.94 % and 61.4kg/hr respectively. The machine comes with a production cost

Groundnut Oil Making Process (Peanut), Business Plan

Raw Peanuts. The complete Groundnut oil extraction process can ensure the nutrition, flavor, safety, and fragrance of peanut oil. The different stages of Groundnut oil extraction process mainly composed of cleaning, shelling, grading, crushing, rolling, steaming or cooking, pressing, filtering and refining. Cleaning:

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

Peanut Oil Making Machines for Sale|Best Manufacturer and Supplier

820. YZS-150. 750-850. 30Kw-6P. 2180*790*1790. 1060. Screw type of oil press machines are the BEST choice for groundnut oil extraction. It uses friction and pressure in th epressing chamber to extract oil from groundnut. The residue or leftover of peanut oil production is known as peanut oil cake.

The main oil crops in Togo is peanut, cotton seed, oil palm, soybean and more. But, the edible oil production industry in Togo is relatively small and its consumption of cooking oil is increasing in these years. So, it is a great opportunity to setup a cooking oil production plant in Togo to get more profits.

Expeller Pressing: A Reliable Method for Efficient Oil Extraction

By Guru July 27, 2023. Expeller pressing is a mechanical method for extracting oil from raw materials, such as seeds, nuts and algae. It is one of the most widely used methods in the oil industry, as it can produce high-quality oils with high efficiency and low cost. In this article, we will explain the expeller pressing technique, its

This Expeller has Two Chambers made of Cast Steel. Feed Side: Ø 16″ x 50″ Long, Discharge Side : Ø 16″ x 50″ Long. Hard Faced Worm Assembly, Discharge Ring. Main Worm Shaft can be withdrawn without disturbing the Gear Box. Chamber Lifting system is motorised. Kettle : 8 Stages with Steam Jackets of Ø 78”for efficient cooking of Seed.

- How does an expeller press work?

- Expeller pressing is based on the principle of applying pressure and friction to the raw materials to squeeze out the oil. An expeller press is a screw-type machine that consists of a barrel, a screw, a hopper, a motor and an outlet. The raw materials are fed into the hopper and then conveyed into the barrel by the screw.

- What is the difference between cold pressed and expeller pressed coconut oil?

- Coconut oil: Coconut oil is one of the most versatile and beneficial oils in the world. It is extracted from the flesh of the coconut by expeller pressing or cold pressing. Expeller-pressed coconut oil has a higher smoke point and a less coconutty flavor than cold-pressed coconut oil, which has a lower smoke point and a more coconutty flavor.

- How many varieties of peanuts are there in Togo?

- (Togo First) – To valorize its peanut sector, Togo adopted earlier this year, new, more productive varieties. A total of 13 varieties from the Mali-based International Crops Research Institute for the Semi-Arid Tropics (ICRISAT), and four from the Senegalese Institute for Agricultural Research (ISRA) were in effect introduced and tested in Togo.

- What is the difference between cold pressed and expeller pressed sesame oil?

- Sesame oil: Sesame oil is one of the most flavorful and aromatic oils in the world. It is extracted from the seeds of the sesame plant by expeller pressing or cold pressing. Expeller-pressed sesame oil has a higher smoke point and a lighter color than cold-pressed sesame oil, which has a lower smoke point and a darker color.