cibu small type soybean oil expeller yzyx90ht in togo

- After-sales Service: Online Service

- Structure: Vertical

- Press Series: First

- Voltage: 220V

- Diameter of Barrel: 150mm

- Loading Capacity: 2kg

- Squeeze Time: 8min

- Nominal Pressure: 55MPa

- Work Pressure: 65t

- Motor Power: 0.75kw

- Heating Power: 0.6kw

- Weight: 250kg

- Dimension (mm): 400*500*850

- Model: Ayz-150tayz-180tayz-230tayz-260tayz-320tayz-360

- Application: Soybean , Soybean , Pine Nuts, Soybean , Peanu

- Features: Automatic

- Name: soybean oil pressing Machine

- Apply: Tung Oil Seed, Soybean Se

- Advantage: High Oil Recovery

- Transport Package: Wooden Case

- Specification: 400*500*850

- Production Capacity: 2-25kg

Cibu Small Type Soybean Oil Expeller Yzyx90-3

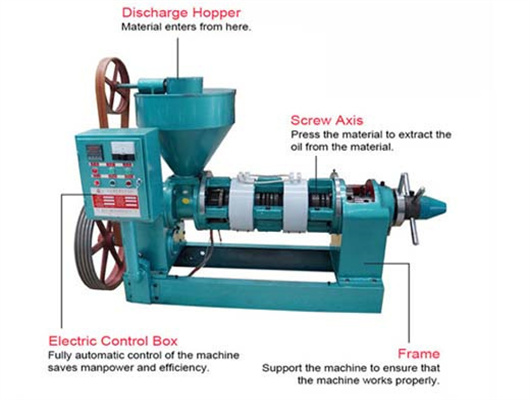

The series YZYX90 & YZYX70 SPIRAL OIL PRESS produced by our company is suitable for squeezing vegetable oil from rapeseed, cottonseed, soybean, shelled peanut, flax seed, tung oil seed, sunflower seed and palm kernel, etc. Spiral oil press has characteristics of small investment, high capacity, strong compatibility and high efficiency. .

The oil extraction by mechanical pressing is the most common method for continuous treatment of oleaginous seeds without solvent. Different types of presses can be used depending on the purpose (expeller, expander, and twin-screw extruder) and on the capacity range (3 kg h−1 to 150 t day−1). At the laboratory scale, many authors have highlighted the effect of operating parameters (screw

NEW Lion™ Expeller® Press - Anderson International Corp

Along with maintenance- and operator-friendly packages, the systems can press over 300 metric tons per day (MTPD) in a single machine with residuals as low as 5% when paired with Anderson’s extrusion technology. With minimal modifications, the Anderson Lion Expeller oil press can change from one oilseed application to another, allowing for

The component hierarchy of domestic oil expeller is given below according to the consisting units for the product: Figure 3: Component hierarchy for domestic oil expeller . Functional decomposition was carried out for individual units of the product. Functional decomposition for heating unit of domestic oil expeller is given below:

Soybean expellers | Hans H. Stein - University of Illinois Urbana-Champaign

Rodriguez, Diego A., Su A Lee, and Hans H. Stein. 2020. Digestibility of amino acids and concentrations of metabolizable energy and net energy are greater in high-shear dry soybean expellers than in soybean meal when fed to growing pigs. Journal of Animal Science, 2020, Vol. 98, No. 7, 1–8.

The heat produced during the oil extraction increases the rumen undegradable protein of the remaining meal. Soybeans are the most prevalent source of protein in North America. Solvent extracted soybean meal is the most widely used ingredient; it is used as a basis of comparison for nutrients and value for other protein products. E/E Soybean

Design and Construction of Oil Expeller Press with Structural

A mechanical oil expeller press was designed, constructed & further analyzed with simulation software (ANSYS) in this research work. This expeller can be useful for small scale oil extraction

The oil recovery efficiency was 72% which results in the annual soybean oil productivity. corresponding to these 6 scales are 4.10, 12.81, 25.62, 89.67, 175.56 and 398.67 million kg, respectively

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- How to extract crude oil from soybean meal?

- The mixture of solvent and fat is then separated to recover the solvent to obtain the crude oil. It is also necessary to recover the solvent in the soybean meal and obtain the solvent extracted meal.

- What solvent is used in soybean extraction?

- In solvent extraction, flaked soybeans are washed with hot solvent, typically hexane, to separate the solids from the fats. Multiple washes dissolve the oil and carry it away. This oil solvent combination is also known as the miscella. The remaining material is the wet meal and solvent, also known as the marc.

- Do soybean expellers need heat treatment after hydrothermical conditioning?

- Different types and degrees of processing conditions may influence digestibility of energy and amino acids (AA) in soybean expellers, but there is a lack of data demonstrating how long heat treatment is needed if soybean expellers are expander processed after hydrothermical conditioning.