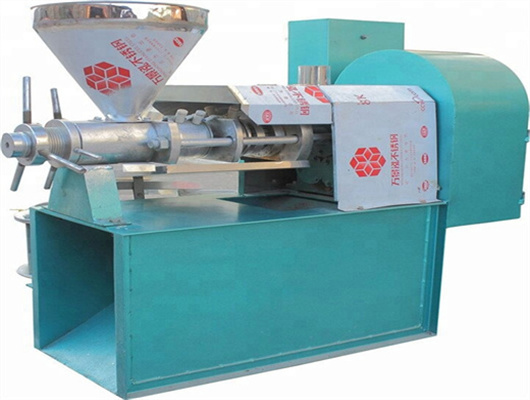

new peanut oil press extraction plant in ghana

- Model Number:6YL-100

- Press Materials: Peanut, All seeds

- Press Series: Fourth

- Suit for: Peanut

- Capacity: 150-200kg/H Oil Extractor Machine

- Function: Extract Crude Oil From Different Oil Seeds

- Advantages of Oil Expeller: Low Oil Residue Rate 6-7% From The Cake

- Accessory Machines: Cleaning, Roaster, Press, Filter, Refinery

- Usage: Edible Oil Processing Factory

- Spare Parts of Oil Expeller: Worms, Rings, Cake Outlet Ring, Rods, Cone

- We Can Provide: Machine Operate Support, Spare Parts Supply

- Working Video: Can Be Provided to You Oil Expeller

- Manual Book: Can Be in English Version

- Transport Package: Wood Fuminicated Box

- Specification: National Standard

- Production Capacity: 5t/D for Oil Seeds

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

The total phenolic compound results indicate that sesame oil had a pronounced rank of kaempferol (2478.44 µg/g) content, followed by canola oil (628.15 µg/g). Also, peanuts oil contains the

Production, Processing, and Food Uses of Peanut Oilseed, Oil,

Peanut oil is considered as a premium edible oil and commands a high price in both US and European markets. In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United

Peanut press machines, like those manufactured by Royal Duyvis Wiener, are the heart of peanut oil production. The process begins with raw materials, primarily peanut kernels. These are fed into the peanut press machine via a feed inlet, and the magic starts to happen. The machine applies pressure on the peanuts, resulting in oil being extracted.

Edible Plant Oil: Global Status, Health Issues, and Perspectives

Pressed extraction of EPOs is the most traditional way to extract oil, and it is also the most widely used method currently (Yara-Varon et al., 2017). Compared with solvent extraction, pressed extraction has the advantages of simple operation, no solvent pollution, high quality of crushed oil, and retention of the unique flavor of EPOs .

Raw Peanuts. The complete Groundnut oil extraction process can ensure the nutrition, flavor, safety, and fragrance of peanut oil. The different stages of Groundnut oil extraction process mainly composed of cleaning, shelling, grading, crushing, rolling, steaming or cooking, pressing, filtering and refining. Cleaning:

latest technology peanut/copra oil extraction plant in ghana

Introduction of Latest Technology Peanut/Copra Oil Extraction Plant . 1) Function: Oil extraction machine is an oil extractor through soaking or spraying pre-pressed cake by a certain organic solvent. The principle of this part is the different solubility of solvent. 2) Use range: Oil extraction machine fits for pre-press extraction of high-oil

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

- What is groundnut oil manufacturing process?

- Groundnut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method.

- How to extract peanut oil from cake?

- The oil and cake are usually collected at the oil outlet and press cake exit /choke gap. After pressing, crude peanut oil still remain impurities in the extracted oil. To aid in the removal of the remaining impurities, oil filter press machines are usually employed.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- How to make peanut oil from groundnuts?

- According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities.