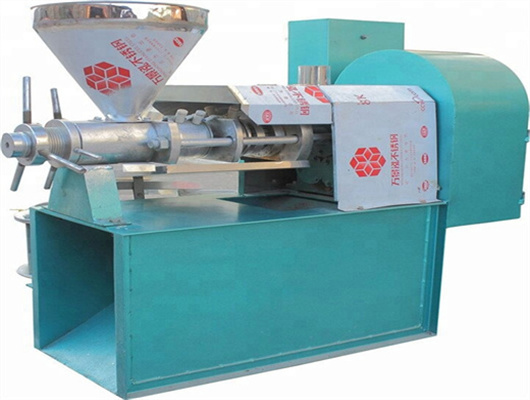

peanut cold pressed oil extraction plant in ethiopia

- Usage: Peanut oil

- Type: Cold & Hot Pressing Machine, Continuous

- Production Capacity: 10-3000TPD

- Voltage: 220V / 380V / 440V

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 120 Tons

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Name: Peanut oil machine

- solvent consumption: 1.5Kg/Ton raw materials

- Oil Color: Yellow

- Oil getting method: pressing/extraction

- Heating way: direct & indirect steam

- Advantage: save water resource

- Bleaching earth consumption: 5~50Kg/T oil

- Steam consumption: very low

- decolor function: to get good color

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

- Local Service Location: India

- Certification: CE/ ISO/ BV

Groundnut Oil Making Process (Peanut), Business Plan

Raw Peanuts. The complete Groundnut oil extraction process can ensure the nutrition, flavor, safety, and fragrance of peanut oil. The different stages of Groundnut oil extraction process mainly composed of cleaning, shelling, grading, crushing, rolling, steaming or cooking, pressing, filtering and refining. Cleaning:

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

Comparison of cold-pressing and soxhlet extraction systems

Antioxidant activities of different nut oils ranged from 11.43 (peanut) to 65.58% (pistachio) in cold pressed oils whereas in case of soxhlet extracted oils they were in the range of 11.32 (hazelnut) to 51.28% (pistachio). β-Carotene contents of oils obtained by cold pressing and soxhlet extraction changed between 7.53 (almond) and 13.58 µg

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. It contains a high protein level (> 25%), and is white to creamy in color due to the mild thermal (< 60°C) treatment (Zheng et al., 2013). Cold pressing of 100 kg peanut kernels can generate 70 kg of defatted peanut

Bioactive Phytochemicals from Peanut Oil Processing By

Soxhlet extraction, hydraulic pressing, screw pressing, and cold pressing are among the methods used for oil production from oleaginous plants. Higher amounts of essential fatty acids and bioactive lipid components were found in the cold-pressed plant oil than in the hot-pressed method .

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Groundnut Oil Extraction Plant | Peanut Oil Processing | Oil

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. The defatted peanut meal contains a high protein level (> 25%) and can be processed into various food products. The objective of this chapter is to introduce the compounds available and the health benefits of cold

- How is peanut oil extracted?

- Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article.

- How is cold pressed peanut oil extracted?

- Commercial cold pressed extraction of peanut oil is carried out using a twin-screw press at temperatures below 60°C ( Wang, Liu, Hu, et al., 2016; Zheng, Ren, Su, Yang, & Zhao, 2013 ). Lastly, a frame filter is used to press and filter three times under 30°C to obtain the cold pressed peanut oil ( Wang, Liu, Hu, et al., 2016 ).

- What is peanut oil processing technology?

- This chapter covers peanut oil processing technology. It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.