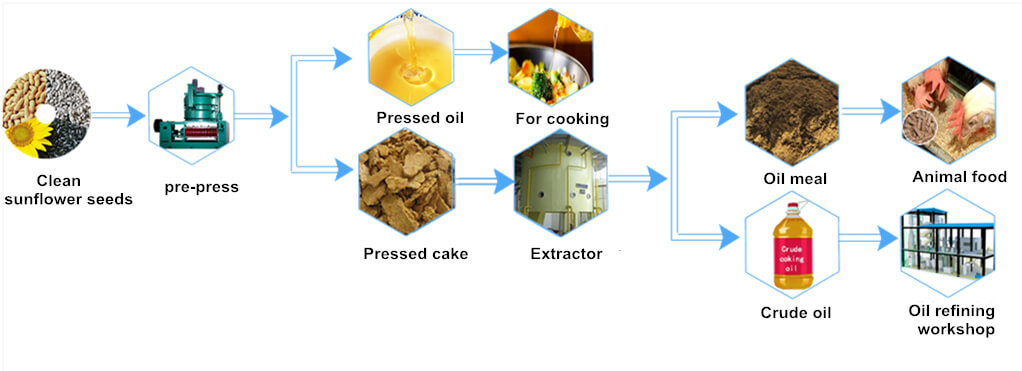

Sunflower Oil Production Line

- Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body, and is beneficial to protect cardiovascular health.

- Service: Customization, installation, guidance, and training

- Cooperation: Factory Directly

- If you are interested in Sunflower Oil Production Line, please leave us a message.

Currently, the sunflower oil sold on the market is mostly produced by de-shelled pre-squeezing and leaching process. De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g. However, by squeezing-leaching seeds with shell, every 100g sunflower oil only contains 41.62mg vitamin E. What’s more, there is no contact with alkane in the process of the un-shelled pressing-leaching process, which avoids the formation of trans fatty acids.

1. Sunflower Seeds Selecting

Select the sunflower seeds with the oil content of 30~50%, and the seed material contains certain impurities (sediment, stones, iron filings, etc.) which should be removed by cleaning sieve and magnetic separator.

Equipment

Oil cleaning sieve, magnetic separator.

Oil cleaning sieve is mainly to remove the impurities in the seed material, and the magnetic separator can remove iron filings.

2. Shelling & Crushing

For sunflower seed, it should be squeezed after shelling, which can increase production capacity and oil quality. After the sunflower seeds are sieved by a vibrating screen and then placed into a vertical centrifugal sheller to separate the shells. After separation, the shell content in the sunflower kernels is less than 10%, and the content of kernels in shells is less than 1%.

3.Sunflower Seed Flaking

Rolling the embryo is to grind the broken oilseeds into embryonic flakes with a certain thickness, which is an important process of pretreatment. Its role is to destroy the cell tissue so that the oil can be easily extracted.

Equipment

Embryo flaking machine

4.Seed Embryo Steaming

Heat treatment is one of the most important processes in the extraction of oils, including the wetting and heating of the sunflower seed. In the production, it is called embryo steaming or frying, and the steamed and fried embryo is called a matured embryo. The heat press of the embryo is called hot pressing and sunflower seeds are mainly hot press. The heat treatment has a direct impact on the smooth progress of the entire oil production process, the level of oil output, and the quality of oil products and cakes.

Equipment

The steam frying pan

5.Pre-squeezing & Leaching

In production, people mainly adopt pre-squeezing and solvent leaching methods for oil extraction of sunflower seed. Pre-press can squeeze out some of the oil in the raw material to improve the oil effect.

Equipment

ZY24(202-3) oil pre-squeezing machine, solvent leaching device.

Process features of ZY24(202-3) oil pre-squeezing machine

(1.) 202-3 type spiral press machine is suitable for pre-squeezing and leaching methods or two times crushing process in the vegetable oil factory, and it is suited to process seeds with high oil content like sunflower seed;

(2.) After pre-squeezing, the structure of squeezed cake is loose but not crushed, which is beneficial to solvent permeation, and the oil content and moisture of cake are suitable for leaching;

(3.) The quality of the extracted oil is better than one squeezing or one leaching of oil.

6. Crude Oil Refining

The steps of sunflower oil refining are basically the same as those of other vegetable oils, including degumming, alkali refining, decolorization, deodorization, and dewaxing. The refined product is not only light in color, but also has high nutritional value and good taste. It is a good edible oil.

Alkali refining pot, degumming machine, decoloration pot, deodorization pot, crystallizing tank, dewaxing press filter, oil pumps and other parts.

Features of Sunflower Oil Production Line

Characteristics of the oil pressing and extracting

Characteristics of the oil refining process