Peanut Oil Production Line

- The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical production”. And the production line can be customer-made according to material variety, factory location, and labor resource.

- Service: Customization, installation, guidance, and training

- Cooperation: Factory Directly

- If you are interested in Peanut Oil Production Line, please leave us a message.

The fragrant peanut oil obtained by pressing process maintains the natural ingredients and aroma of peanut oil, and it is rich in antioxidant vitamin E and has a long shelf life, so there is no need to add chemical antioxidants for storage; it is a pure natural oil products that are produced by combination of modern and traditional technology. With the improvement of living standards, the fragrant peanut oil is deeply loved by consumers for its unique pure fragrant flavor and have a broad market prospect.

Peanut Oil Production Process and Operating Points

In order to ensure the nutrition, flavor, and safety of fragrant peanut oil and reduce the cost, we adopt a physical squeezed method in the peanut oil production line. And the features of the pressing line are: (1) Extraction adopts pure physical pressing method to completely avoids the contact of raw materials and chemical solvents throughout the entire production process; (2) To abolish the unfavorable refining process which affects the quality of finished oil, such as solvent leaching, alkali refining and deodorization, so as to ensure the natural nutrients in the refined oil. (3) The refined oil is stored in an underground storage and the cooling water coil technology is used to ensure long-term storage.

1. Production Processes

1.1 Raw Material

The raw material which is used to produce fragrant peanut oil is fresh, full-grained, undamaged, mildew-free, free of insects and has not undergone an aging period. Raw materials would be cleaned by removing immature, damaged, and moldy grains during the cleaning process.

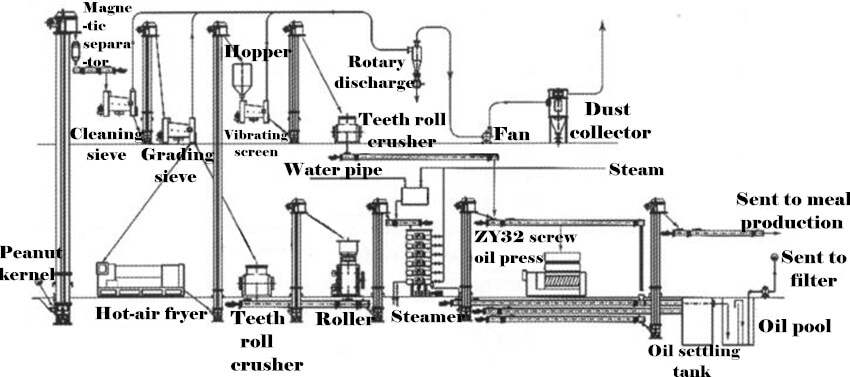

1.2 Process Flow of Peanut Oil Production Line

1.3 Process Parameters and Procedures

Peanuts are cleaned and shelled, medium-sized peanuts are screened (about 25% of the treated amount), and the rest are large- and small-sized peanuts (about 75% of the treated amount). The large-sized and small-sized peanuts are broken, rolled and steamed. The medium-sized peanuts are crushed and cleaned by red skin eliminator, then being baked. Finally, the three sized materials are mixed and then pressed in the press to obtain the crude oil. After pressing, the oil is settled and filtered to produce a fragrant peanut oil.

1.4 Operating Points

(1) Cleaning

Stones, metals, etc. may damage mechanical equipment; moldy, insect-infested peanuts will seriously affect the quality of the oil. In order to reduce oil loss, improve oil yield, ensure high quality of oil, and prolong the service life of equipment, the cleaning process should be strictly controlled. Metals could be removed by magnetic separation, using magnets to remove magnetic impurities in raw materials. Other impurities like stones are removed by self-regulation vibrating sieve, using peanuts and impurities’ difference in the particle size and weight, with the help of peanuts and impurities in the relative movement of the screen surface.

- Equipment: Self-regulation vibrating sieve, magnetic separator

Self-regulation vibrating sieve is widely used for separating impurities of large, medium and little-sized in grain, the machine has many features like the simple structure, smooth operation, low noises and consumption, good cleaning results, etc.

The magnetic separator has the horizontal and vertical type. The separator is made of stainless steel, and the raw peanut flows through the body and the magnet separator extracts contaminants.

(2) Shelling

n order to increase the oil yield, improve the quality of the oil and cake, reduce the equipment wear, increase the effective production capacity of the equipment, and facilitate the follow-up processes such as embryo rolling, the peanuts are shelled after cleaning.

- Equipment: Peanut shelling machine

The shelling machine consists of racks, fans, rotors, single-phase motors, screens (number two), feed hoppers, vibrating screens, V-belts and its transmission belts.

- Working principle

The peanuts are fed continuously and fall into the coarse grating firstly. Due to the force between the rotation of the stainless steel plate and the fixed grating, the peanut shells are separated from the kernels, then peanut kernels and shells pass through the grid at the same time. After they pass through the air duct, most of the peanut shells are blown out of the machine by wind, and unshelled kernels and some unpeeled peanuts fall into the gravity sorting screen together. After re-screening, the peanut kernels are separated by the screen and passed through the outlet, and flowed into the sacks. The unpeeled would flow into the hoist, and then into the fine-grained grid to perform secondary shelling. Then through screening, you can achieve full stripping.

(3) Grading

The large and small peanuts are then separated by vibrating screen and as a raw embryo material in the main processing line, the middle size peanut for frying materials in the deputy processing line, the two processing line are treated separately. The ratio of raw embryo material to hot air baked material is 3:1.

- Equipment: Peanut kernel grading machine

This machine uses five-layer folding structure and the automatic feeding device, four to five different sizes of peanut kernels can be screened at a time, and by changing the screen pieces, can achieve the required screening purpose. Peanut kernel grader has characteristics of the compact and reasonable structure, high efficiency, low cost, convenient and reliable use, which is applicable to select peanut, via a selection can achieve precise classification standard.

(4) Crushing

The purpose of crushing is to remove peanut’s skins, after crushing, the red skins can be sucked out by a wind separator, and the separated peanut red skin can be used as the raw material in medicine and chemical industry. Through crushing, the large-sized peanuts have a smaller size. Peanuts could be broken into 4 to 6 pieces, and moisture of crushing is controlled in 7% to 12%.

- Equipment: Peanut crushing machine

Double-pair tooth roller crushing is the key process of oil preparation for large grain (soybean, peanut) oil crops in oil processing enterprises. The crushing effect directly affects the quality and output of the rolling process. The crusher can meet the crushing demand of different output of 20T~1500T per day.

- Features of peanut crushing machine

- The whole machine adopts full sealing safety protection.

- The crushing roller is cast by centrifugal composite technique, using high alloy wear-resistant material.

- Reasonable tooth pitch was designed so that the crushing effect and output reached perfect combination.

- The bearing adopts SKF imported original product, automatic cooling of bearing belt fan, lubrication technology in bearing collection, which can be maintained under working condition

(5) Rolling

After crushing, peanuts are rolled through the instantaneous extrusion force between the two rollers to form the embryo slice, the shape of the peanut is changed, the oil path is shortened, which is beneficial to the oil extraction. Please note: The embryo slice which can be sieved through 1mm sieve hole is not more than 10~15%, and the embryo thickness is below 0.15mm.

Equipment: Peanut rolling machine

Peanut rolling machine is used for the processing of oil embryo pieces. The embryo rolling machine consists of a feeding device, a roller device, a hydraulic device, an adjusting mechanism and a transmission device. The start-up, operation, feeding, rollers tightening. and rollers loosening of the rolling mill are all controlled by the electrical control system program. The machine has reliable quality, simple operation, compact structure, beautiful appearance, low noise, stable operation and high output.

(6) Steaming and baking

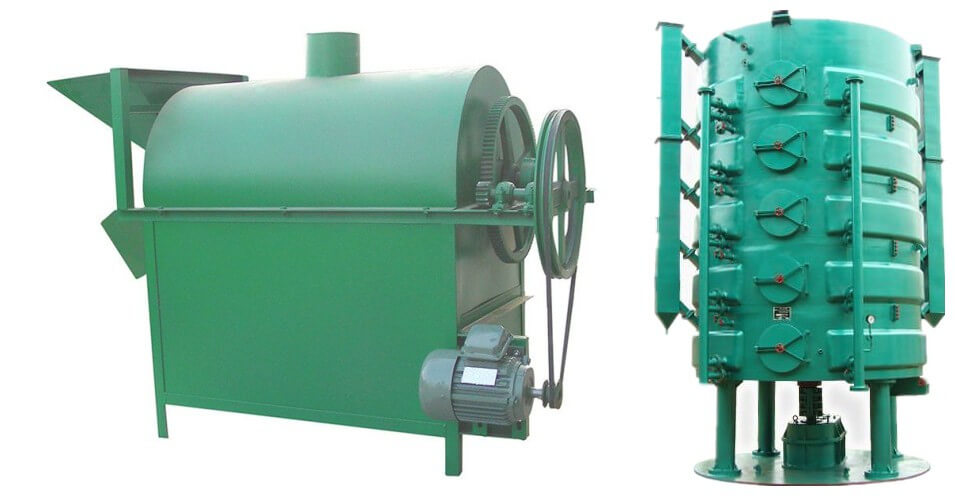

Steaming and baking process are divided into two processing lines.

Equipment: Peanut baking machine, ZCL steaming cooker

(7) Pressing

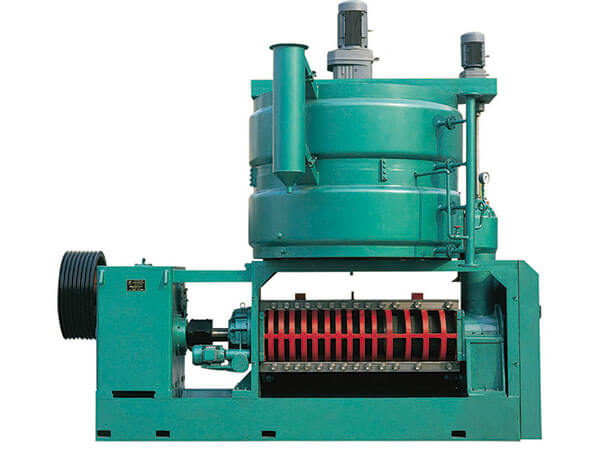

The steamed peanut is then pressed by expeller for oil extraction. Using a mechanical screw press, the original cell structure of the peanut is destroyed under mechanical force to obtain a pressed crude oil.

Equipment: ZY32 type screw oil press

ZY32 spiral oil press is a large-scale continuous oil extraction equipment. It has passed ISO9001-2000 quality system certification and is suitable for pressing high oil-containing seeds such as cottonseed, rapeseed, ramie, sunflower seeds, and peanuts. With the features of large processing capacity, low power consumption, low operating cost, loose cake structure without breaking, easy solvent penetration, low residual oil rate, etc., ZY32 type screw oil press is an ideal oil extraction equipment for large-scale oil plants.

(8) Refining

After a long period of precipitation, the crude oil can be filtered by a vertical leaf filter and sent to a refining plant. The pressed cake can be crushed and sent to a leaching plant for secondary leaching. Leached oil is refined and sold as ordinary oil.

1. Crude oil refining process flow

Filtration of oil→primary cooling→adding filter aids→secondary cooling→48h precipitation→filtration→refined oil→filter cake

1.5 Peanut Oil Storage

The appropriate condition for peanut oil storage is 8% moisture content and the temperature which does not exceed 20℃. Sealed storage can prevent the infection of pests and the influence of the outside temperature and humidity, which is conducive to maintaining a low temperature.

Peanut oil is stored at a temperature below 15℃ in a sealed container to prevent lipase hydrolysis and oxidation, and to avoid the increase in acid number and peroxide value. The average temperature of the ground below 4m is below 20℃, so the storage house is built underground.