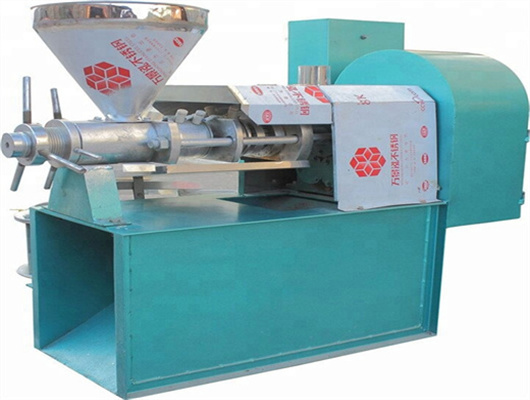

new type oil extraction plant peanut in cape town

- Usage: professional manafacture for Peanut oil production line

- Type: professional manafacture for Peanut oil production line

- Production Capacity: 1-1000TPD

- Voltage: 380v/440v or local voltage

- Power(W): Depend on the machine capacity everyday

- Dimension(L*W*H): Depend on the machine capacity everyday

- Weight: Depend on the machine capacity

- Product name: Professional manafacture for Peanut oil production line

- Application: Oil Production Line

- Advantage: High Oilput

- space requirement: 60-80 square meter for

- Delivery time: 30-70 days

- Machinery type: Making oil Machine

- Oil residual in the cake: 7-8%

- Export markets: Southeast Asia and other places

- Color: Customers' Request

Groundnut Oil Manufacturing Process With Flowchart - Goyum

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Depending on the variety and other cultivation details, peanut kernels contain between 45 to 55% oil, with the Spanish variety typically boasting the highest oil content. While many peanut oil mills rely on the traditional double press method, some plants are turning to high-shear dry extrusion to streamline the process.

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

Groundnuts (peanuts) – Agribook Digital

Groundnuts (peanuts) are a high value crop that can be marketed with little processing but are extremely versatile and can be used in a wide range of products. The oil made from them can be used for cooking and they can be used to make peanut butter. Oil extracted from the groundnut can also be used as raw material for manufacturing of soap

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

Phenolic Fraction from Peanut (Arachis hypogaea L.) By-product

The extract exhibited potent activity against the clinically isolate H1N1 virus from 2009 pandemic, with synergistic effect when combined with the approved anti-influenza drugs, oseltamivir and amantadine, implying that peanut skin extracts may have potential application in the development of new therapeutic approaches for influenza management (Makau et al., 2018).

Fragrant Peanut Oil Production Line. The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.

- Where are peanuts grown?

- Peanuts ( Arachis hypogaea L.) are an important agricultural crop that is grown worldwide, being the third largest source of plant proteins in the human diet, which amounts to around 11% of the global protein supply [ 1 ]. Peanut is widely planted in the warm climates of Asia, Africa, Australia, North America, and South America.

- How is peanut oil extracted?

- Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent ( n -hexane) extraction [ 29 ]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

- How can aqueous enzymatic extraction improve the function of Peanut proteins?

- Discuss extraction methods, modifications and applications of peanut proteins. Aqueous enzymatic extraction can efficiently separate oils and peanut proteins. The functionality of peanut proteins was significantly improved after modification. Native and modified peanut proteins can be used for a variety of purposes in foods.