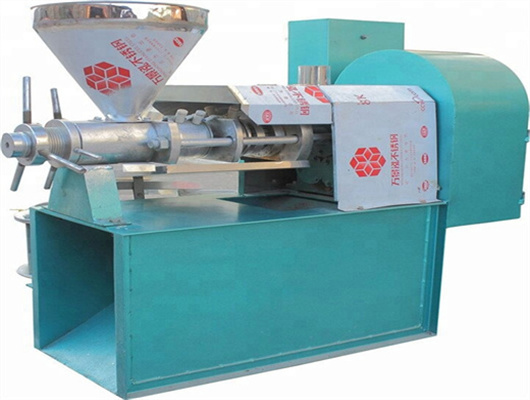

peanut oil extraction plant vegetable oil line in cameroon

- Usage: Peanut Oil manufacturing line

- Type: Peanut Oil Pressing Machine

- Production Capacity: 100 kg/h - 1000kg/h

- Voltage: 380V,440V

- Power(W): according to capacity

- Dimension(L*W*H): 1360*950*1170mm

- Weight: according to capacity

- Certification: CE,ISO9001

- Capacity: 1-1000TPD

- Application: Peanut Oil manufacturing line

- Function: extract oil from seed

- Operation mode: Electricity drive

- Machine Name: Peanut Oil manufacturing line

- Processing type: Solvent extraction

- Residual oil in meal: ≤ 1%

- Solvent consumption: ≤ 3Kg/T

- Steam consumption: ≤ 3kg/t

- Power consumption: ≤ 15KWh/T

Defatting and Defatted Peanuts: A Critical Review on Methods of Oil

As consumers increasingly seek out plant-based foods for their potential This review elucidates the methods used for extracting peanut oil, Oil is in line. with national. standards. 39.8%

Summary This chapter contains sections titled: Peanut production, history, and oil extraction Oil uses Composition of groundnut oil Chemical and physical characteristics of groundnut oil Health iss...

Production, Processing, and Food Uses of Peanut Oilseed, Oil,

In 2018, peanut oil sold for US$1470/MT in the United States and for US$1326 in Rotterdam. Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization.

Vietina, Agrimonti and Marmiroli [77] extracted DNA from sunflower, soybean, peanut, sesame, hazelnut, soybean, pumpkin, rice and olive oils, and then amplified the DNA fragments from these oils to identify adulteration of olive oils, and the results showed that the DNA-based method could quickly and effectively identify the adulterations in olive oils by comparing the DNA melting profiles of

Optimization Methods for the Extraction of Vegetable Oils: A Review

Processes 2020, 8, 209 2 of 21 processing of oils from oilseeds, extraction remains one of the most critical steps because it determines the quality and quantity of the oil extracted.

Most seed oils are edible while some are used generally as raw material for soap production, chocolate, margarine, and recently in biodiesel formulations as potential candidates capable of replacing fossil fuels which are costly and destructive to the environment. Oilseeds are a green and major reservoir which when properly exploited can be used sustainably for the production of chemicals at

Edible Plant Oil: Global Status, Health Issues, and Perspectives

Oil-seed camellia, oil palm, olive, and coconut (Cocos nucifera) are the four well-known woody edible oil plants in the world, as they possess a high oil content. Among bulk herbaceous edible oils, the unsaturated fatty acids (UFAs) are the highest, approaching 80%, in peanut oil and rapeseed oil.

The yield of free oil extracted from roasted peanut (150 °C, 20 min) using the AEP method was around 92.2% using the optimized processing conditions: solids-to-liquid ratio = 1:5; pH = 9; temperature = 60 °C, and time = 2 h [33]. Liu et al. (2020) investigated a combination of AEP and membrane separation for peanut protein extraction.

- How is peanut oil extracted?

- Peanut oil is recovered primarily by expeller pressing or in combination with hexane extraction. Only four plants process peanut oil in the United States. Peanut oil is processed by conventional caustic refining, adsorbent bleaching, and deodorization. The food uses of peanut oil and protein are reviewed in this article.

- Is oil extraction from peanuts environmentally friendly and cost-efficient?

- A comparison in terms of productivity, efficacy, specificity, quality of the extracts, and operating conditions was conducted, which favored the novel methods as being mostly environmentally friendly and cost-efficient. Chemical methods of oil extraction from peanuts.

- What technology is used in peanut oil production?

- It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment. 3.1.

- What is peanut oil extraction technology?

- Peanut Oil Extraction Technology The leaching method, also named the extraction method, is a method that uses certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials so as to eventually separate the fat from the materials.