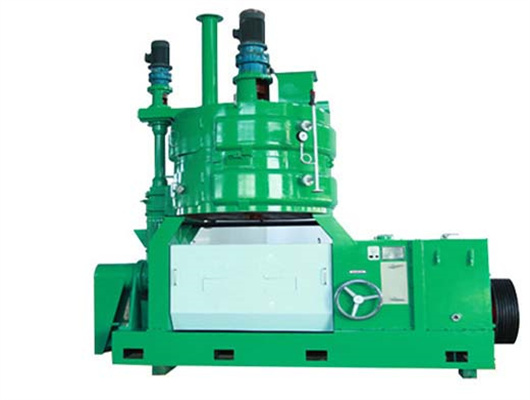

cotton soybean cotton oil processing equipment in kenya

- Usage: for soybean

- Voltage: 220V

- Dimension(L*W*H): 38*18*28cm

- Weight: 12KG

- Warranty of core components: 6 Months

- Core Components: Motor

- Oil type: Soybean Oil

- key words1: oil press machine design

- key words2: Soybean oil press

- key words3: automatic oil press

- key words4: house hold oil pressing machine

- key words5: cold oil press machine dubai

- key words6: oil press machine china

- key words7: oil press machine china online

- key words8: oil press machine cost

- key words9: home oil press machine buy online

- key words10: oil press machine automatic

- After Warranty Service: Video technical support, Online support

- Certification: CE

Steps of Cottonseed Oil Processing Process | Oilmillmachinery.net

Flaking: To make cracked Cotton seeds kernel pcs into uniform smaller flakes with thickness ≤ 0.5mm, less powder, non-oil spilled, pinching softly by hand and the ratio of smaller powder than 1mm sieve mesh is ≤ 10% - -15%. Cooking: The process is to add the steam into the crushed/flaked seeds pcs, then to dry the seeds for getting rid off

The ideal temperature range for growing cotton in Kenya is between 20°C-28°C. The crop also requires moderate to high rainfall, preferably between 600mm-1000mm per annum. Cotton plants require adequate water supply especially during the period of boll formation since it affects the quality and yield of the cotton fibers produced.

Cotton processing and ginning – Kenya Yearbook Editorial Board

The ginner’s objective is to produce lint of satisfactory quality and to gin the cotton with minimum effect on fiber spinning quality. There are 24 ginneries in the country, with an installed capacity of approximately 140,000 bales annually. Out of the 24 registered ginneries, only about 10 ginneries are currently operational.

First in oil with Alfa Laval. Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil. Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities. Improved sustainability and reduced operational costs thanks to unique technologies

The journey of cotton processing in Kenya - UndaMeta Limited

The journey of cotton processing in Kenya. Man spinning cotton through a thread spool. Image: Pexels/ Julie Krabbe Clausen. Author: Dr. Francisca Odundo; Editor: Teresa Lubano. Date: March 1, 2023. The visit. I had anticipated that the area around the entrance to the textile factory would be filled with an unwelcome cacophony of ear-splitting

Kenyan textile mills for making yarn while cotton seed is sold to Kenyan oil mills for the processing of edible oils, cattle cakes, soap, chicken feed etc. Ginneries also prepare, among other things cotton seed for distribution to farmers for planting purposes. The ginned cotton seed is dressed with copper fungicide

Frequently Asked Questions on Bt Cotton in Kenya

27. 7. 3. Cotton is 95% self-pollinated, greatly reducing the chances of Bt cotton crossing with conventional cotton varieties. To conserve conventional varieties, the county has a national gene bank, a repository where biological material is collected, stored, catalogued and made available for redistribution.

Mini Slovent Extractor Machine Set. Small Complete Solvent Extraction Plant. Production Output: 500kg ~20ton/day (Batch Extraction Process) Application: It is widely used to extract more oil from the cotton seed cake, soybean seed cake etc. (the residual oil ratio in final oil meal can reach to 1%) Normally, after oil pressing or expelling

- What are the policy issues affecting cotton production ecosystem in Kenya?

- The lack of certified seed has culminated to low productivity of the cotton crop. Some of the policy issues which impact on cotton production ecosystem in Kenya include lack of access to subsidies and credit for inputs and a liberalized price-guiding mechanism for harvested seed cotton.

- Is seed cotton enough for ginning capacity in Kenya?

- The local supply of seed cotton is not enough to meet ginning capacity. Before sub-sector liberalization, over 90% of Kenya¡¯s ginneries were owned by farmer cooperatives who also marketed cotton for farmers. However, most Cooperatives ceased operations after the sub-sector downturn when farmers transitioned away from cotton cultivation.

- What are the main inputs for cotton production in Kenya?

- Major inputs include fibres (natural/man made), dyes, chemicals, yarns, threads, fabrics, utilities such as water, electricity and fuel, machinery and skilled and semi skilled labor. Cotton growing in Kenya is mainly undertaken by small-scale farmers Interventions by the Government under the Third Medium Term Plan (MTP III) are bearing fruit.

- Why is cotton a strategic crop in Kenya?

- Cotton is an industrial cash crop grown by small scale farmers in Kenya largely under rain-fed conditions. It is considered a strategic crop for communities in the ASALs (marginal areas). These areas have low potential for arable farming and the population living in these areas is resource poor.